The long-awaited opening of the TWA Hotel has arrived. We’re proud to unveil the work we had the pleasure of producing for this iconic and historic landmark at JFK Airport in New York City that has been restored and reimagined as a first-class hotel. From planning the placement of more than 500 custom shower drains to their installation, this project was one for the books. Our work included the concept development, specification, production, and installation education – all of which were completed in record time. Read on to learn more about the grand opening, hotel highlights, and the installation process.

The Grand Opening

The TWA Flight Center, which first opened in 1962, was known for its standout white-winged architecture designed by Eero Saarinen.

Image Credit: TWA Hotel

Although it has been closed since 2001, the historic landmark itself has been preserved. (You may recognize the space from the 2002 Leonardo DiCaprio film, “Catch Me If You Can.”)

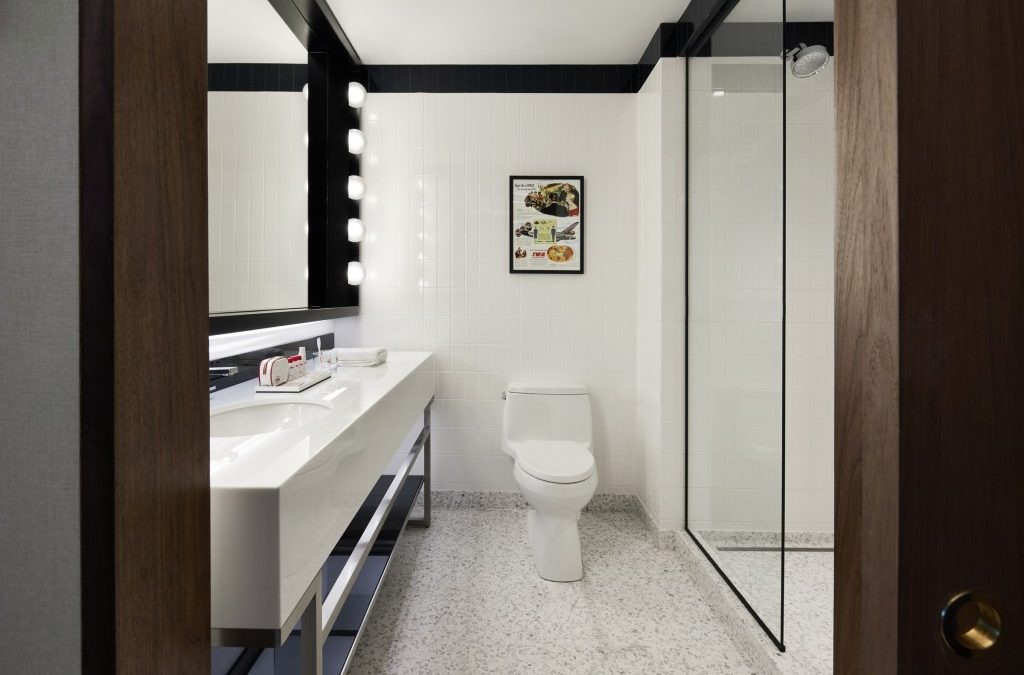

The opening of the transformed hotel features new amenities but retains the mid-century modern, 1960s charm that will have guests feeling as if they’ve been transported back to a time when passenger air travel was the epitome of luxury.

The rooms feature an exhilarating glimpse of the JFK International Airport runway, where you can see planes taking off. And thanks to soundproof technology, you won’t hear a single thing. (It doesn’t get much cooler than that.) The hotel has a rooftop infinity pool and event space that has been quickly catching the eyes of top fashion designers as a dreamy runway destination, as well as the world’s biggest hotel gym: a 10,000-square-foot fitness center. The rooms feature retro nods to the 1950s and 1960s with Knoll furniture and rotary phones.

Image Credit: David Mitchell for TWA Hotel

Infinity Drain Installation

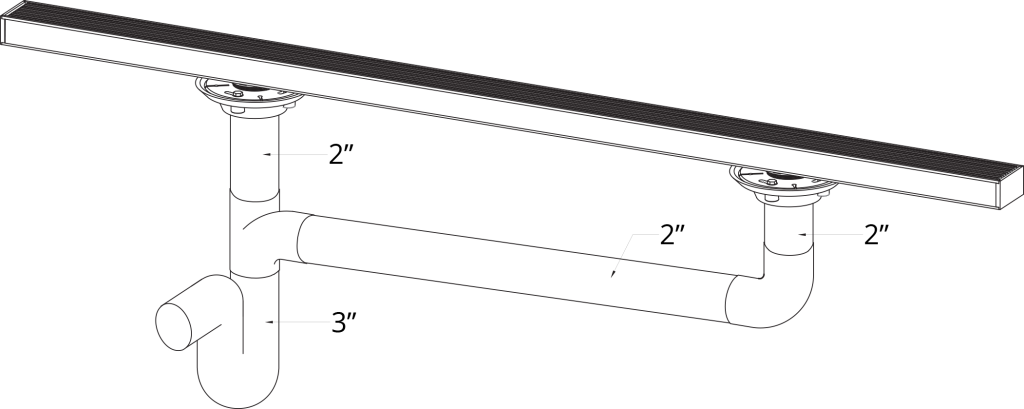

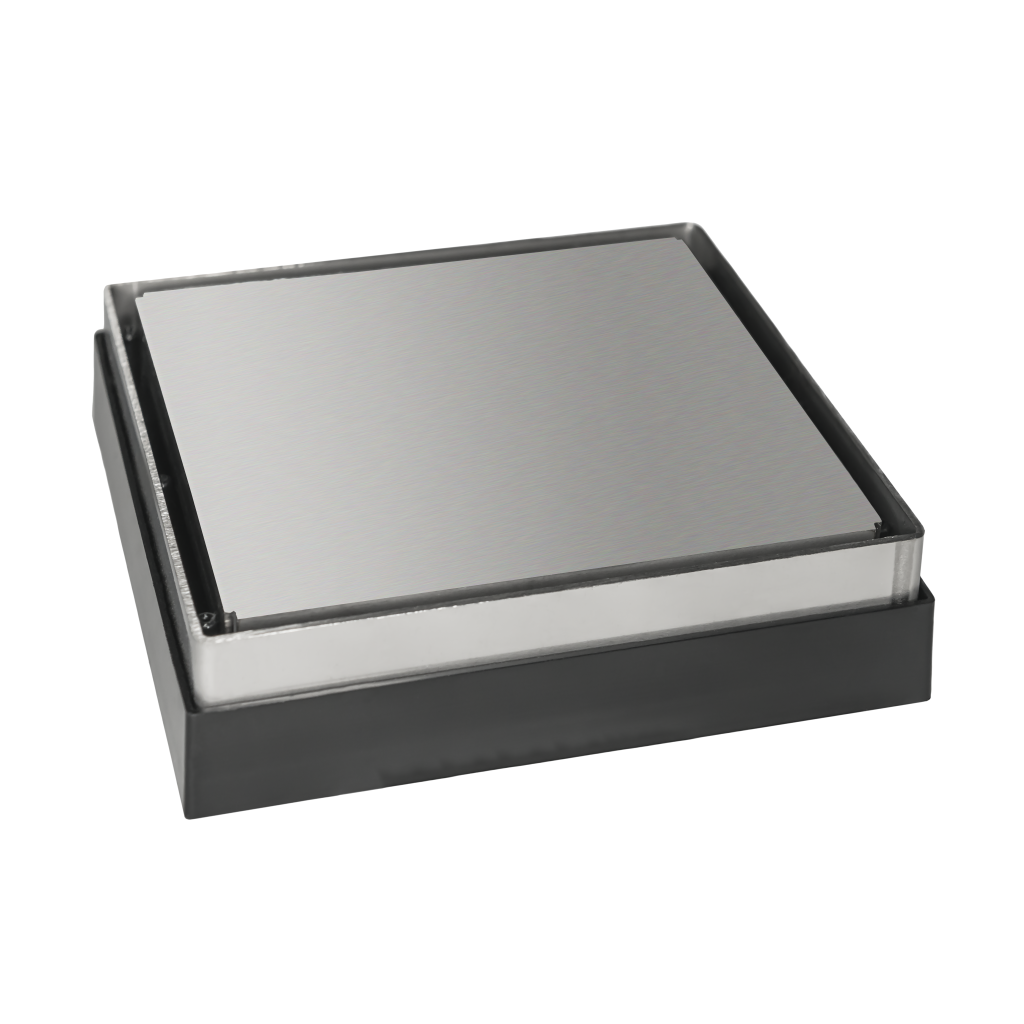

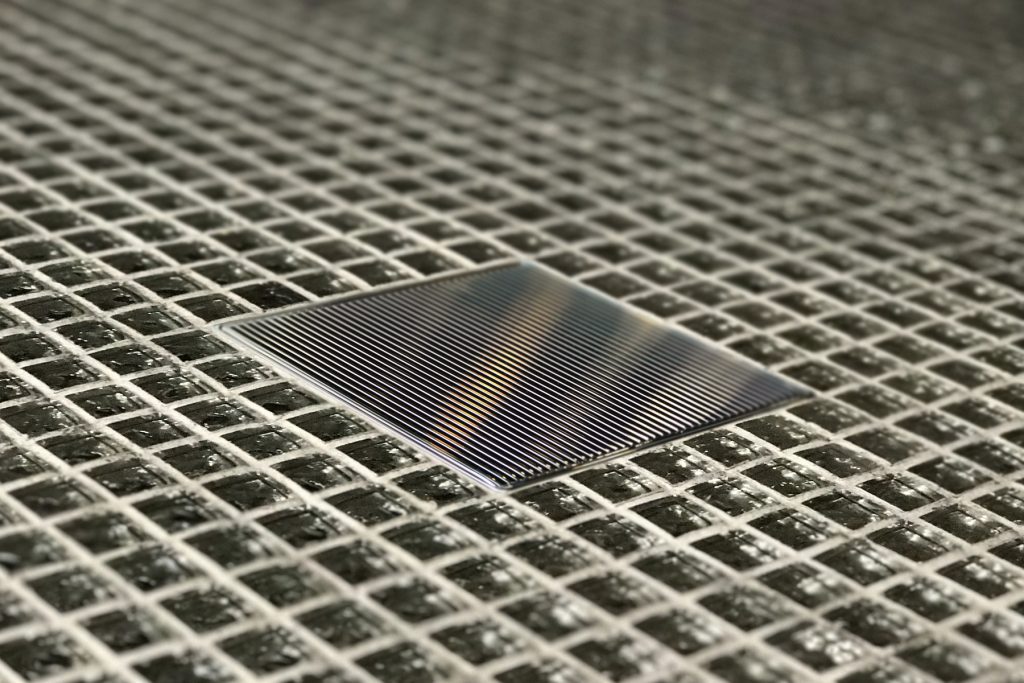

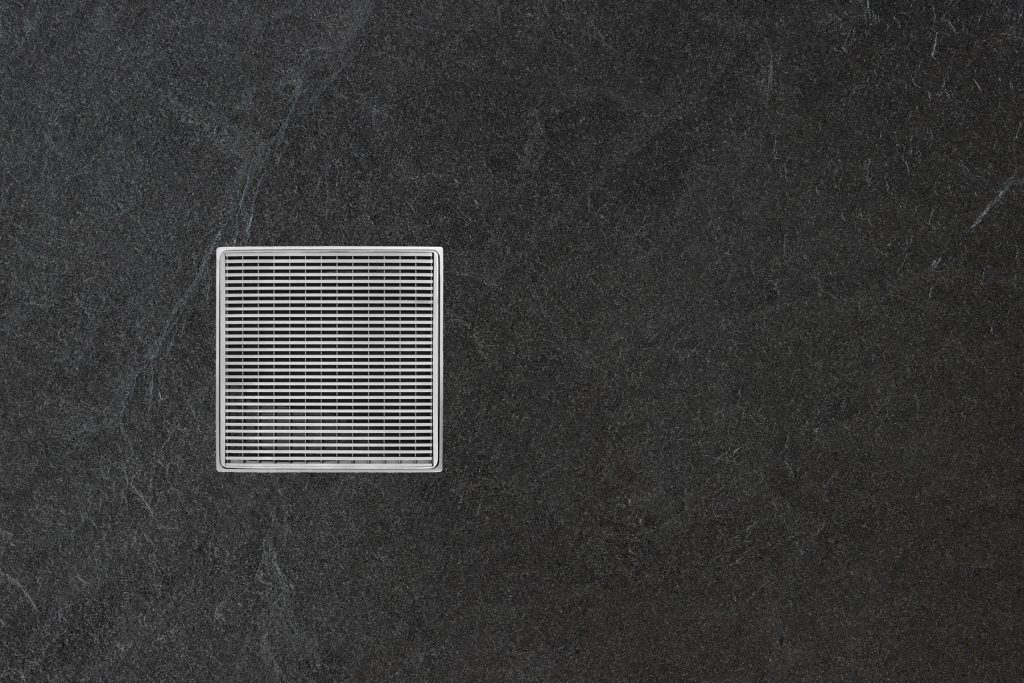

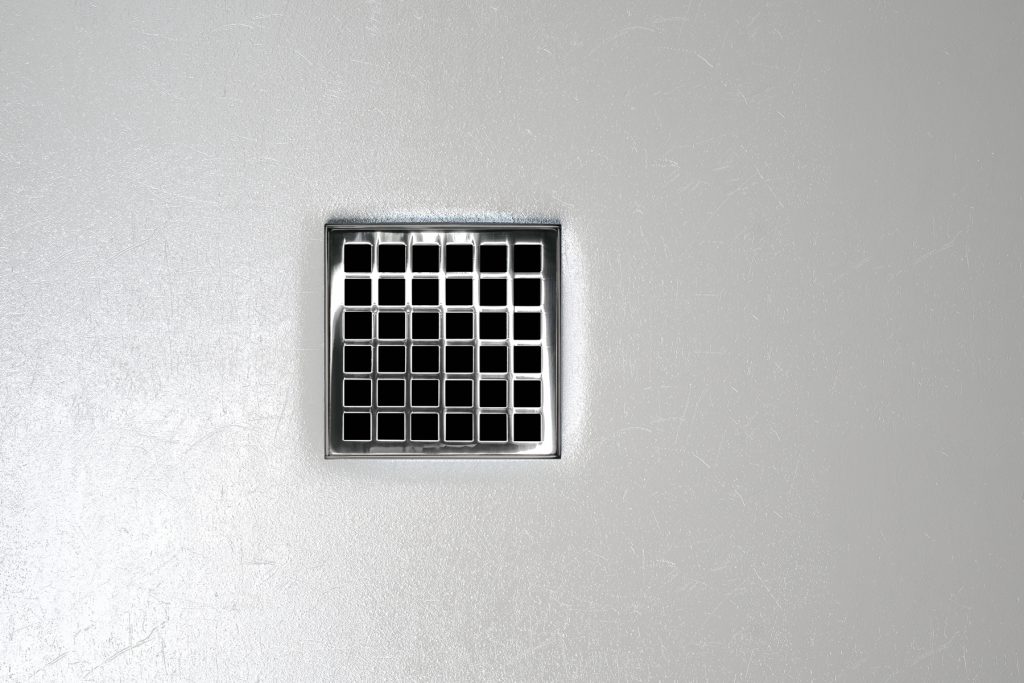

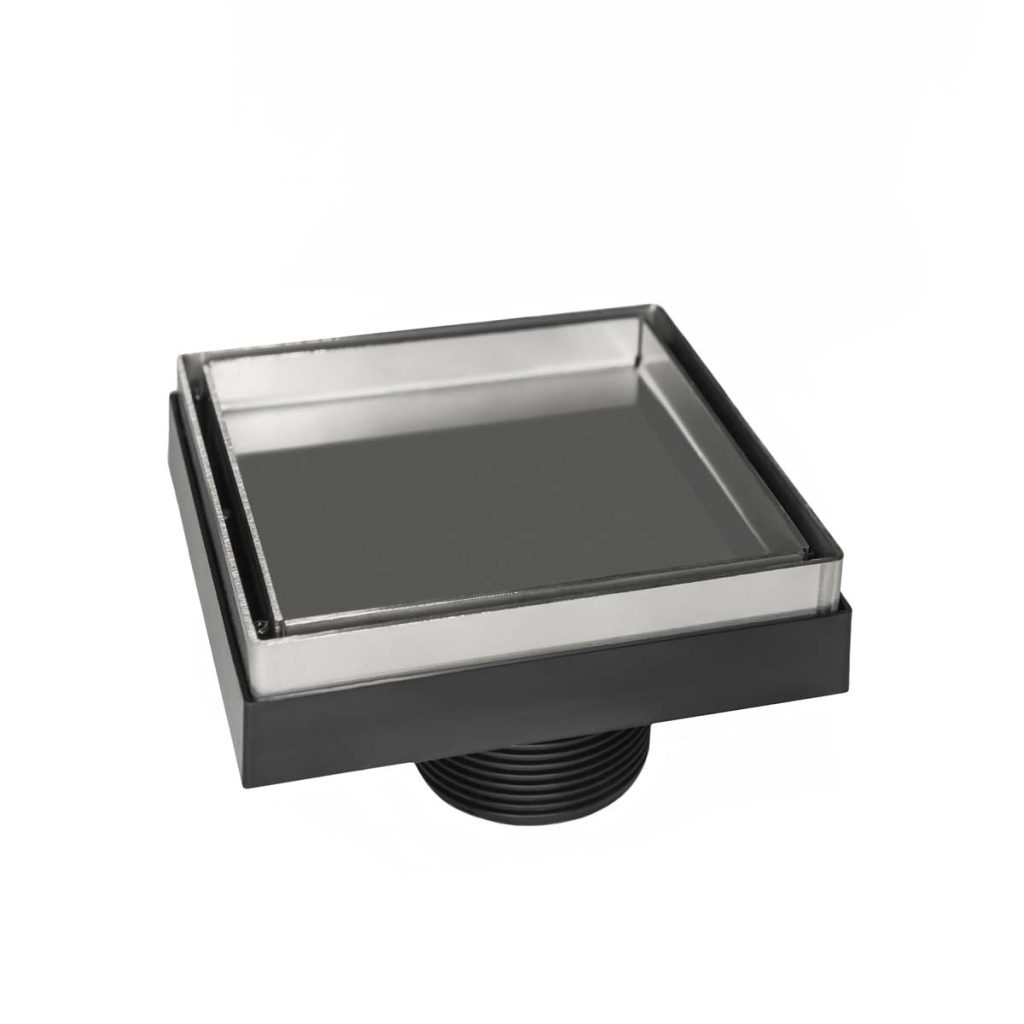

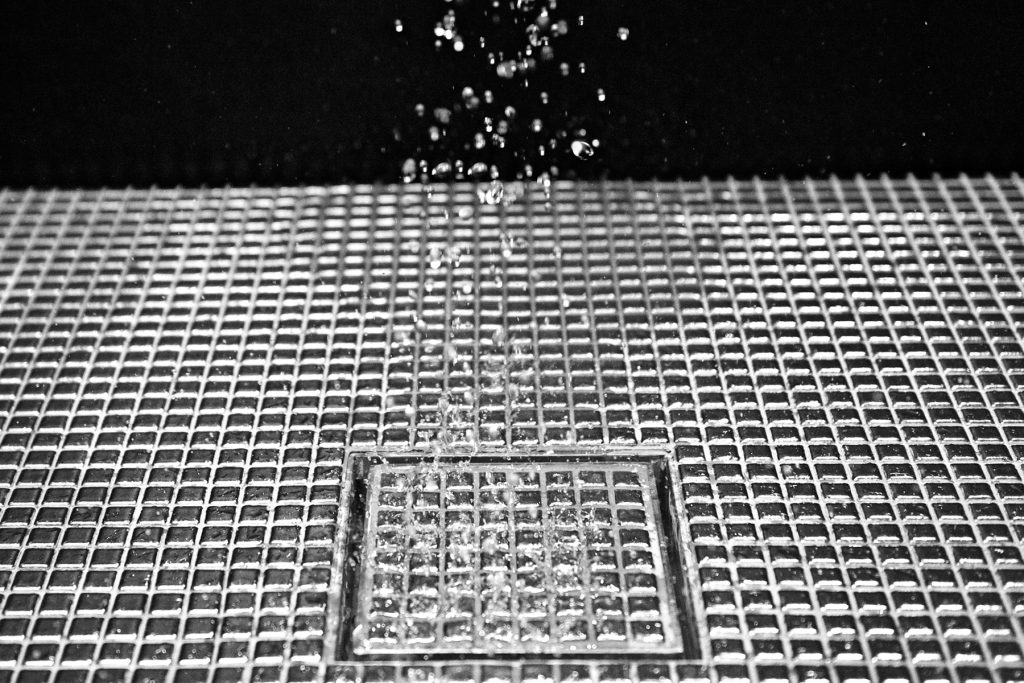

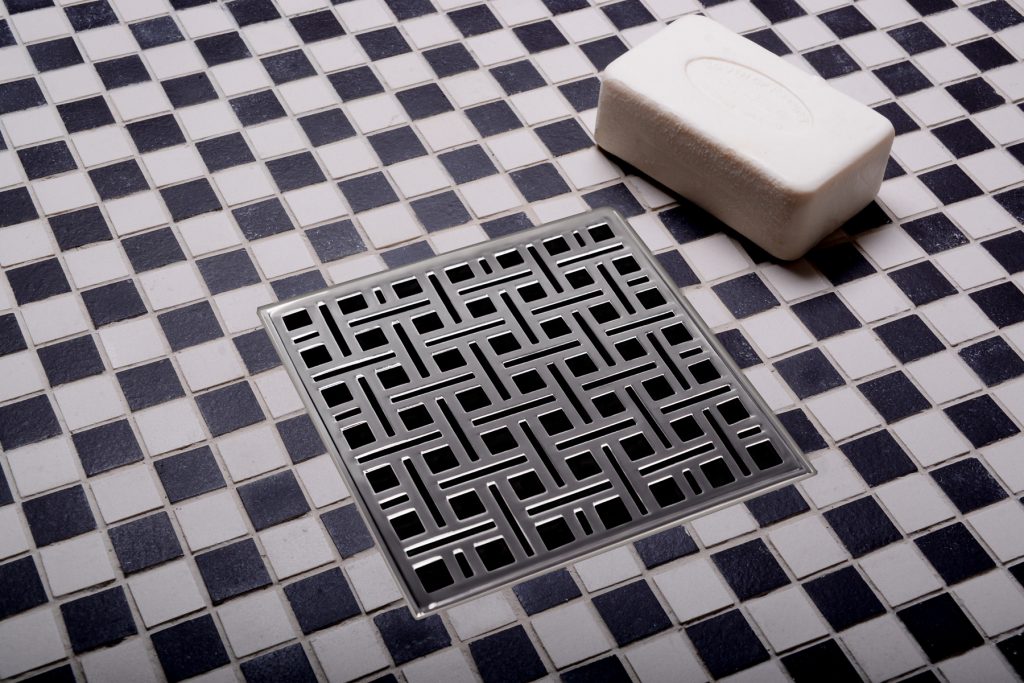

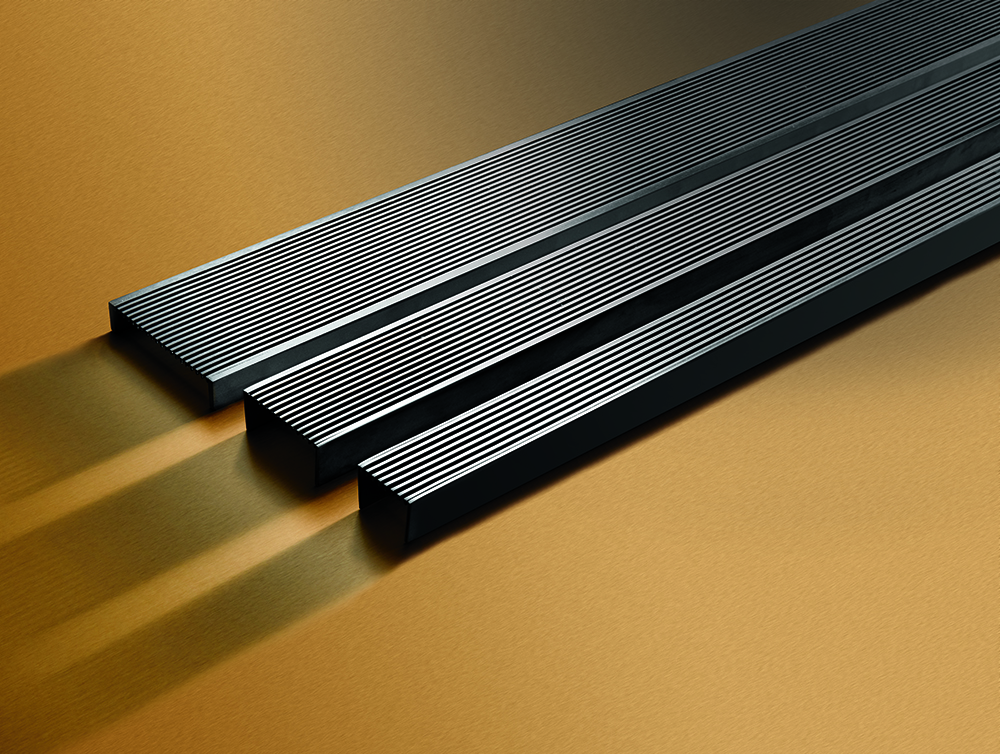

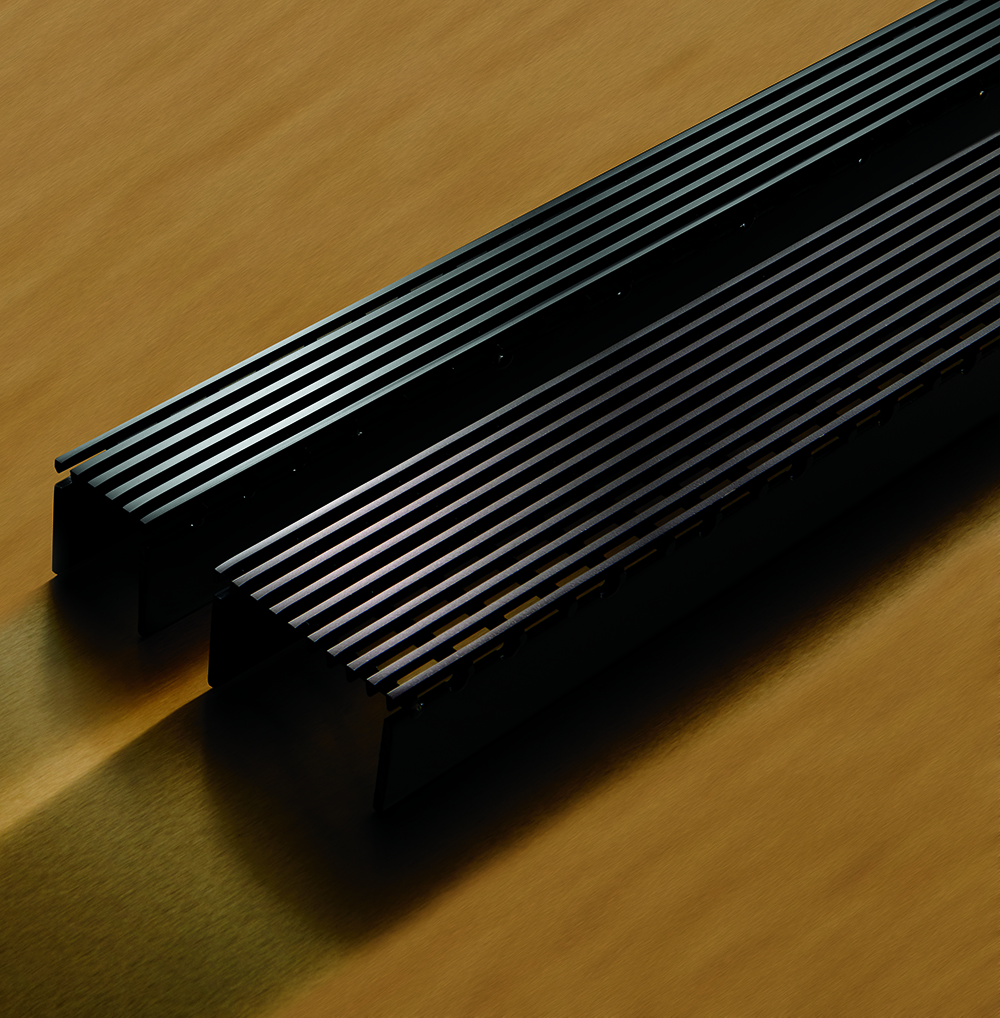

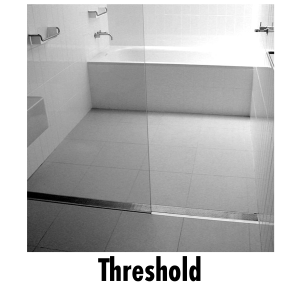

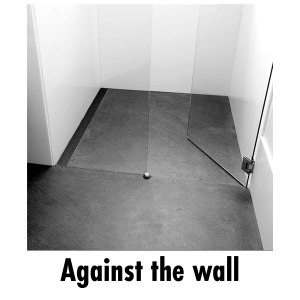

The USG Durock™ Brand Infinity Drain® Shower System and linear shower drains were specified for all 512 guestrooms. This project required the inclusion of both curbed and ADA compliant curbless showers on every floor to allow accessible options for all guests.

Given the proximity of our Long Island, New York-based team and manufacturing facility, we were able to deliver this project – which typically takes three-to-four years – in under one year, with the production and installation of approximately 40 drains (about one full floor) per week.

Each of the 512 linear shower drain channels were customized to fit perfectly into the sanitary cove flooring of the bathrooms.

We’re so honored to have been a part of renovating this historic property. Our dedication to innovation is what keeps us at the top of the linear drain market. Visit our website to learn more about how our custom linear drains can help streamline your next project. Contact us, find a dealer, or check out our installation guides today.